usp class vi elastomers

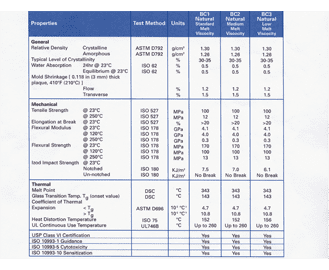

A durable thermoplastic with balanced mechanical properties and fine-feature surface resolution. Adjunct membership is for researchers employed by other institutions who collaborate with IDM Members to the extent that some of their own staff andor postgraduate students may work within the IDM.

O Rings Fda And Usp Class Vi Darcoid Rubber Company Oakland California

FDA USP Class VI and ADI Free EPDM Wetted Elastomers.

. USP Class VI elastomers. USP Class VI Internally Lubricated EPDM. Capable of meeting UPS Class VI.

Originally hosted July 27 2020. Drainability A sanitary heat exchanger a sanitary flush pressure transducer and pitched piping are included to ensure all equipment can be drained effectively. USP Class VI applies to one of the six classifications for plastics from General Chapter 88 of the United States Pharmacopeia and National Formulary USP-NF.

ISO 10993-5 for cytotoxicity. Expanding temperature capabilities specifically with FKM and FFKM elastomers. FDAUSP Class VIADI-free Types T205 and T205M can be used in applications requiring clean regulator solutions.

Ethylene-Vinyl Acetate EVA Thermoplastic Elastomers TPE Classified USP Class VI. Medical device manufacturer Boddingtons Plastics offers Class 7 cleanroom manufacturing for the production of Class 1 and Class 2 medical devices in a state-of-the-art facility in South East England. Kurarays medical-grade TPEs further comply with USP Class VI requirements and have been assigned to FDA Drug master file.

Pharmacopeia USP a non-profit organization whose standards inform decision-making at the US. USP Class VIFDA 21 CFR 177-2600EC1935-2004ADIREACHRoHS. FDA USP Class VI-70 to 250 Black EJ273-70 Chloramine Resistant -70 to 250 Black EJ274-70 Internally lubed NSF 61 Chloramine Resistant-70 to 250 Black E0740-75 Nuclear Applications -70 to 250 Black E0515-80 NAS.

Basic Properties of Elastomers International Elastomer Abbreviations Technical Education O-rings and rubber Quality Services Quality Services. Metal seals are also discussed in this recording. Division offers a wide range of polymers and additives to the medical device and industrial sectors with FDA and USP Class VI approvals to.

Easy conversion between constructions Converts easily from the Types T205 and T205M to the Types T205H and T205HM with two O-rings and one machine screw. Product wetted elastomers to USP Class VI. 1x MPC Coupling 14 with Sealing Cap exclusively used for filling the.

Specialty compounds designed to offer resistance to extreme chemicals bases steam explosive decompression as well as low temperature conductive and nonconductive properties. UL 1203 for explosion-proof. MIL-STD-810G for fungus resistance.

Originally hosted November 18 2020. Learn more about our polishing and finishing. Food and Drug Administration FDA.

MIL-STD-883J for thermal stability. Over the past 20 years SSP has formulated and manufactured more than 1000 different silicone compounds. As two of the most commonly used elastomers both Viton and nitrile o rings have some fantastic properties.

The biocompatibility of Kurarays medical-grade TPEs is studied according to ISO 10993 including ISO 10993-4 hemolysis -5 cytotoxicity -10 skin sensitization and -11 pyrogen. But in Viton vs nitrile o rings which is best. When the surface area of the the class designation of a plastic must be accompanied by specimen cannot be determined use 01 g of elastomer oran indication of the temperature of extraction eg IV-121 02 g of plastic or other material for every mL of extraction which represents a class IV plastic extracted at 121 or I-fluid.

2 to 38 psig 014 to 26 bar set pressure range MR98H. FAR 25853a for flame retardancy. Elastomers as well as examples of typical O-ring applications fundamentals of static and dynamic seal design and O-ring failure.

The W range consists of 17 standard models with pressure and flow capacities to 15 bar 218 psi 50 Hz and to 725 m3h 191525 galh 50 Hz and a number of special versions which may be specifically adapted to customer requirements. These specialty compounds are designed to adhere to dissimilar substrates resist exposure to sterilization and. CellGenix GMP DC is produced following all applicable GMP guidelines and allows for the safe use in accordance with USP Chapter and ISO Technical Standard 20399.

FDA and USP Class VI elastomersincluding white silicone black EPDM and black Viton Surface finishes are to the degree of polish required by the project from 50Ra to 10Ra or lower and including H-Electropolish. The Institute comprises 33 Full and 13 Associate Members with 12 Affiliate Members from departments within the University of Cape Town and 12 Adjunct Members based nationally or internationally. USP Class VI refers to a set of biocompatibility testing requirements from the US.

15 to 200 psig 10 to 138 bar set pressure range. Master Bond offers USP Class VI approved one and two component adhesives sealants and coatings formulated for the assembly of medical devices. Larger stainless steel reservoirs.

Kalrez 6221 parts are thermally stable up to 260C 500F permitting them to be used in Stage II Sterilization processes where other elastomers lose their sealing ability. ポリエステル系熱可塑性エラストマーThermoplastic polyester elastomers TPCは結晶性セグメントと非晶性セグメントを持つ直鎖状のブロック共重合体で各セグメントはTPCに弾性を付与し加工しやすくする役割を果たします. SSPs silicone elastomers are high-purity cost-effective silicones that meet precise application requirements for material properties curing profile platinum or peroxide and color.

KTW FDA USP Class VI EB152-70 3407 General Purpose -70 to 250 Black EJ273-70 Chloramine Resistant -70 to 250 Black EJ274-70 Internally lubed NSF 61 -70 to 250 Black Chloramine Resistant. UL 94V-0. Specifically USP publishes test instructions for the plastics polymers and elastomers that are used in medical devices and.

For 3-year terms which are renewable. Available Backpressure Constructions MR98L. 3-A.

We also offer certifiable compounds that meet AMS 3216G USP class VI FDA compliant Dupont Company U2A and SU2A sheet specification. For real world functional testing and low to mid-volume production runs. Constructions available with FDAUSP Class VI approved ADI-free elastomers.

44 0 1909 560 203. 3-AUSP Class VIFDA 21 CFR 177-2600ADIREACHRoHS. USP Class VI for biocompatibility.

Chapter 88 sets out standards for testing and certification of a material to be utilised in a medical device. DuPont Kalrez 6221 parts are especially suited for Water for Injection WFI systems Steam-in-Place SIP cleaning and other critical systems. Polyurethane elastomers have excellent wear resistance high tensile strength and high elasticity in comparison with any other elastomers.

FDA CFR 175300.

![]()

Ssp 2390 Series Specialty Silicone Products Inc

Iso 10993 Vs Usp Class Vi Medical Molding And Bicompatible Rubber The Rubber Group

Looking Beyond Usp Class Vi Testing What Is Usp 87 Testing Holland Applied Technologies

Usp Class Vi What Is It And How Does It Apply To Elastomers Barnwell

Usp Class Vi What Is It And How Does It Apply To Elastomers Barnwell

Fda Usda Nsf51 Usp Class Vi Compliant Seals Products

Usp Class Vi Testing Aft Fluorotec

Usp31nf26s1 C1031 General Chapters 1031 The Biocompatibility Of Materials Used In Drug Containers Medical Devices And Implants

Usp Class Vi Standard Anderson Negele North America

Biopharmaceutical Usp Class Vi Gaskets Newman Sanitary Gasket

Pharmaceutical And Cosmetics Production

Why You Need Certified Usp Class Vi Silicones Specialty Silicone Products Inc

Parker V1274 75 Usp Class Vi Biocompatibility O Ring United Seal

Usp Class Vi Standard Anderson Negele North America

Usp31nf26s1 C1031 General Chapters 1031 The Biocompatibility Of Materials Used In Drug Containers Medical Devices And Implants